- Multiple-printhead connection, up to four printheads.

- Functional, versatile and competent to diverse printing applications.

- Combination of different printhead systems.

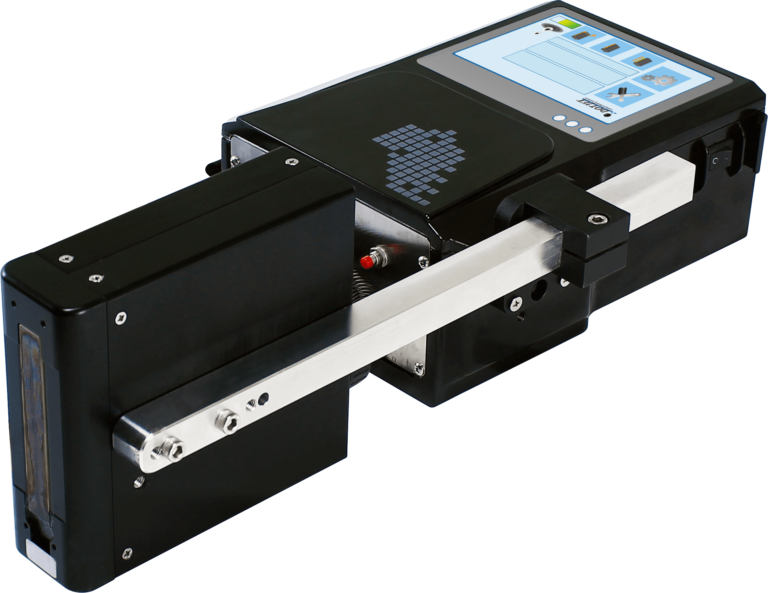

The DJ2400 high-resolution printer system is designed to connect to multiple piezo inkjet printhead systems to an IPC controller. That means, users can create print templates for a larger print location. Direct coding and marking on secondary packaging with the DJ2400 will help users reduce the burden of preprinted boxes and labels. Its IPC controller screen can be remotely monitored and operated through the Dotjet’s Inkjet CMD System.